Meh

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Fishing Tips, Advice and Articles

Blogs

Store

Posts posted by Meh

-

-

The Cooks has been pretty slow of late. Try blades in the deeper sections.

BTW every time I read of people taking fish home from the Cooks I cringe a little.

For your own benefit don't do it. With the pesticides and heavy metal levels that ARE present in fish from the Cooks you're asking for trouble.

-

The Cooks is fishable as of yesterday. Should be good by the weekend.

-

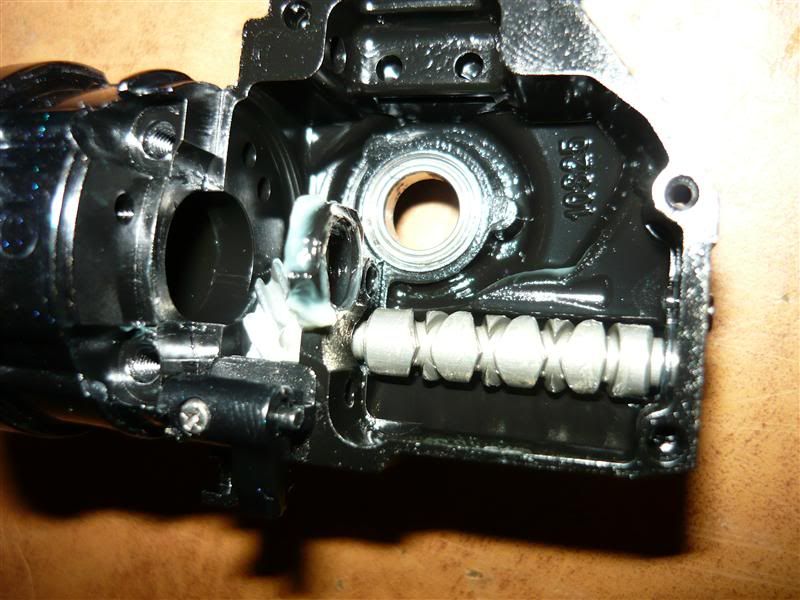

Corrosion Repair

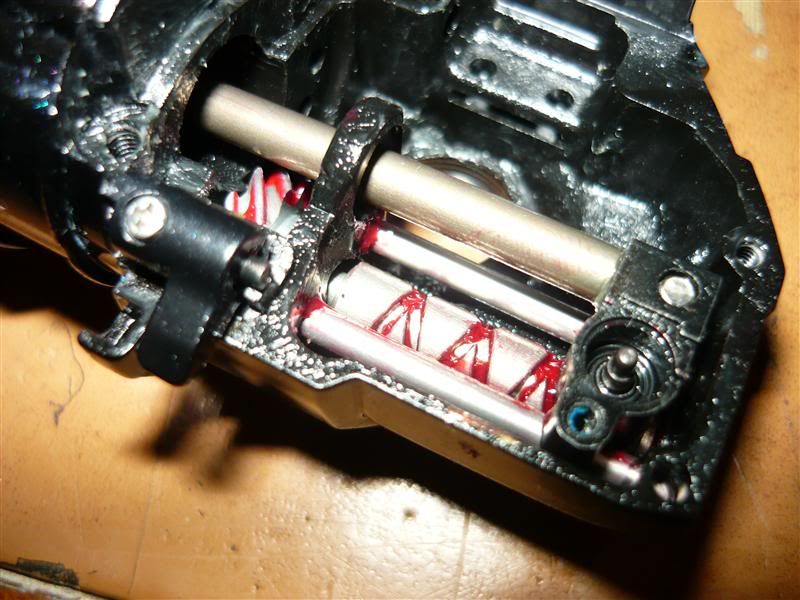

About a year ago I dropped the base of the reel into some wet sand.

The sand and salt found its way through the two drainage holes in the rear protector.

I had intended to clean this out but it slipped my mind meaning that the salt and sand rattled around i the small cavity and eventually the inevitable happened.

The internals of the reel were still in prefect condition no sand or other material has got in, if the corrosion was allowed to continue it would have become a problem.

Firstly I extremely lightly ground away the corroded material until the intact magnesium was exposed.

I used a diamond bit in a dremel set on the lowest speed.

After grinding the affected area and the edges of paint surrounding it was was lightly sanded then cleaned with wax and grease remover.

I then coated the sanded area with a high strength 2 part epoxy. Araldite wont cut it.

Because the inner bearing surface was affected I could not just coat it with epoxy and let it cure as the bearing would no longer fit, and even if i sanded it back it would be impossible to get perfect and the alignment would be thrown out.

The solution I came up with was to use a drill bit as a reverse mold/alignment tool of sorts.

Drill bits are made to precise tolerances and once the epoxy has cured around it a perfect surface will be left behind.

The bearings on either end of the worm shaft are 6mm so I used a 6mm drill bit.

To prevent the epoxy permanently attaching the drill bit to the body it needed to be coated with something to stop it sticking.

I used some mold release and then dipped it in PVA. This is how boat builders prevent fiberglass sticking to their molds.

You must let the PVA dry first.

I was a little worried this method would increase the diameter of the drill bit enough to result in a poor fit, this was not the case it was a perfect fit.

The drill bit used was a new 6mm Sutton. The shank (smooth part) was just long enough to reach between the upper and lower bearing housings to allow perfect alignment between the two.

After the epoxy had cured I gently twisted the drill to break it free and slid it out.

I then cleaned out the hole to remove any mold release. Sanded back the epoxy flush with the original surface with a flat jewelers file and 400 sand paper then thoroughly cleaned the entire body.

Then it was ready for re-assembly.

Wrong side, but you get the point.

-

IMG]http://img.photobucket.com/albums/v37/n000b/P1000548.jpg[/img]

The body is complete, you may want to check the rotor assembly I didnt feel the need, I did clean and re oil the line roller bearings and carriers.

This photo is not the correct order, check the Schematic.

Finished

-

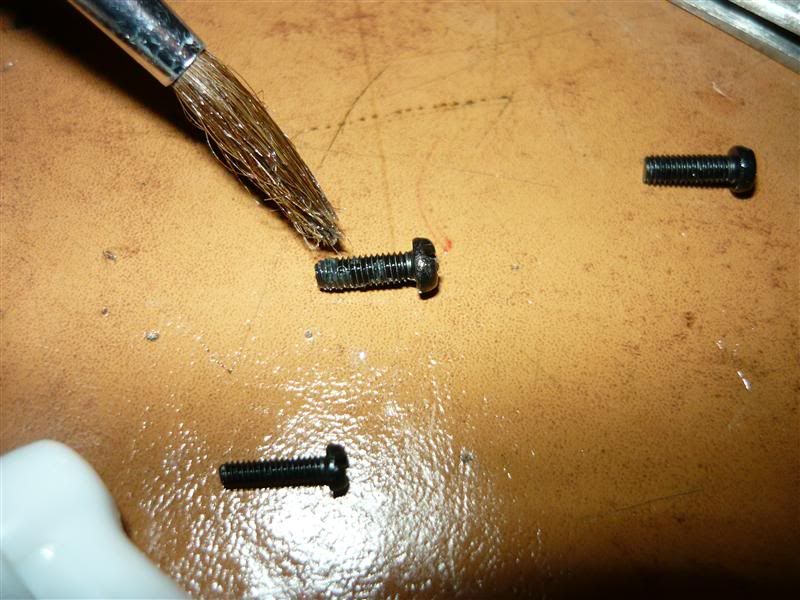

I grease the threads on all external screws.

I also greased under the rear protector to help prevent corrosion occurring again.

The old rear protector was a little scratched so I ordered a new one (same as 2500 Size)

-

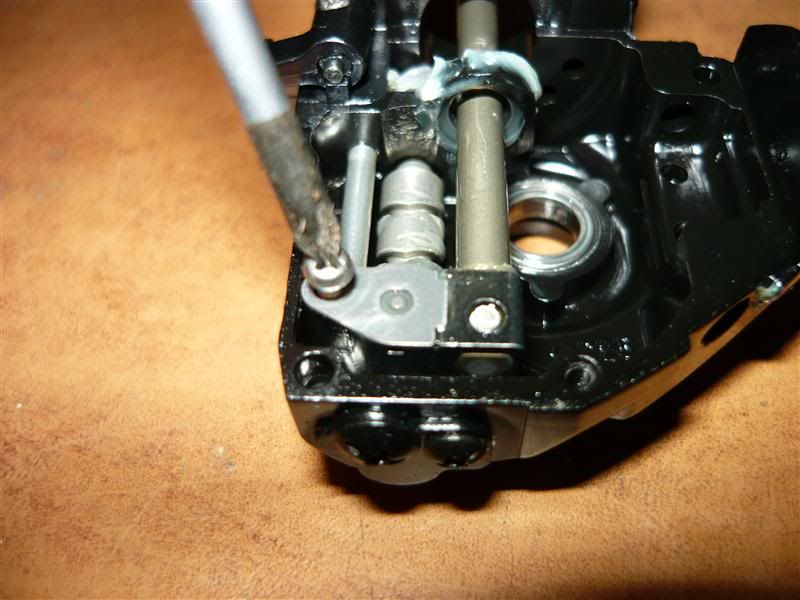

Push out the worm shaft then take out the idle gear, not a complete photo but its fairly obvious once you start.

Ok, now comes the time to put it all back together.

The assembly will mostly be photos as it is essentially the reverse of what has just been explained.

Start by cleaning all parts (bearings, gears etc.) thoroughly with Carburetor cleaner if you don't have this you could use another suitable solvent. An ultrasonic cleaner would be even better.

Using some heavy non water soluble grease to coat the inside of the reel. I used Cals drag grease

Oil all bearings before re-assembly. I used Shimano oil with a few drops of hot sauce oil. I didn't use hot sauce straight because although it is suited for spool bearings on bait casters IMO it is too thin for this application.

I used hot sauce grease on all gears.

-

Take out the rear protector collar and screw.

Undo the oscillating slider, slide off the lower pinion gear bearing.

Take off the oscillating pawl cover and take out the pawl assembly. (I didn't get a photo of the full assembly. Check the schematic)

Take off the worm screw retainer (be careful there is a tiny washer under it.)

Slide out the two oscillating guides.

About a year ago i dropped the base of the reel in some wet sand and some corrosion has started. (I will show the repair at the end of the post.)

Slide out the main shaft. All parts are not shown.

Should look like this.

-

Remove the body flange seal to access the rear protector screw.

Remove the rear protector and shield.

Undo the side plate screws and take off the side plate.

Note the side plate seal.

Take out the drive gear. Note the location of the washer.

-

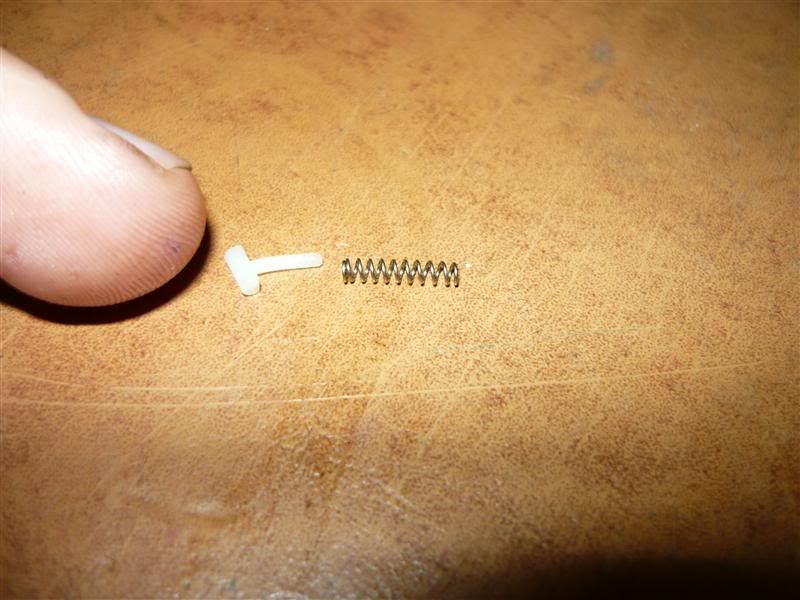

Very carefully remove the roller clutch assembly, there are 6 tiny springs and a washer that you really don't want to lose .

Undo the bearing retainer screws and take off the retainer.

Remove the Anti reverse spring and guide. Be careful with this it will shoot out and believe me you wont find it.

Slide out the pinion gear and bearing.

Take off the friction ring and remove the friction ring spacer to access the side plate screws.

-

After owning this reel for a little over a year I decided it was time for a service.

So here goes...

Note: the 2000 size Stella shares the same body as the 2500 so all parts in the reel besides the rotor are available from Shimano Australia.

Shimano didn't tell me this but were otherwise very helpful and the parts I ordered showed up very quickly.

Tools I used.

First remove the spool to expose the spool bearing assembly.

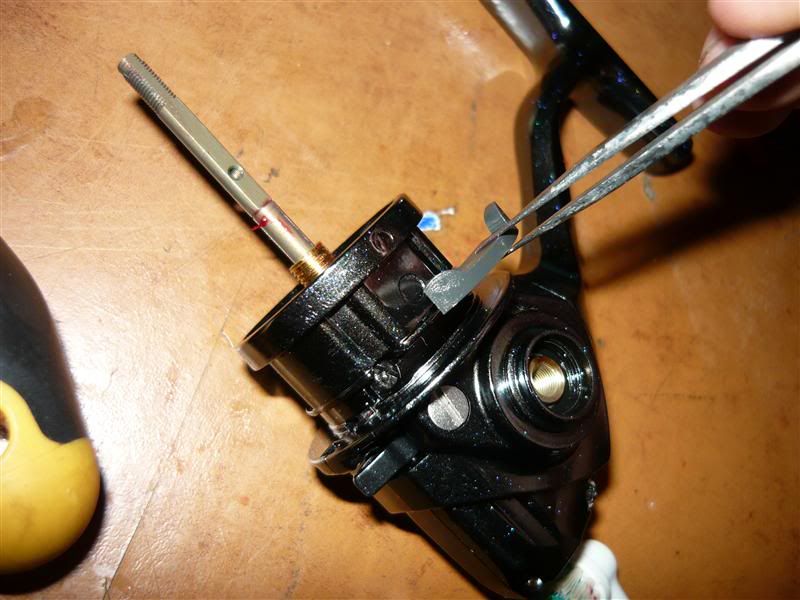

To get the assembly off remove the the spool washers and then wind out the small grub screw. I didn't have the correct size allen key handy so i used a pair of fine tweezers to wind it out.

Remove the rotor nut lock plate.

Undo the rotor nut remembering that it is a REVERSE THREAD to undo it you must turn it in a clockwise direction.

This is best done with a socket, you can do it with a small shifter provided you are careful.

You can now remove the rotor assembly.

Next remove the roller clutch waterproof retainer and spool support.

Be careful with the seal and spacer.

-

Went for a fish with Swordfisherman who kindly offered me a spot on his boat.

Started off very cold by the time we got to the first spot my hands weren't working.

Started off a bit slow so we moved to another spot. First cast at the new spot and Stewy though he was snagged, until big headshakes zzzzzz then pylon.

Must have been a sizeable fish, Stewy was cursing the bust off all day haha.

Went on to have a decent session further up river with bream, whiting, flathead, trevalley and Stew even managed a rather fat looking blackfish on a plastic.

-

Good too see some nice trevors around. I might have to brave the morning cold and give it a crack.

-

You may want to have a look at W hooks, they are a decent compromise between a treble and single and you also do away with split rings.

I have used them on smaller poppers and hardbodies, I am not sure how they go in heavier gauges though.

-

I wouldn't want to be connected to anything large with 30kgs of drag, recipe for disaster if you ask me.

For example, this guy can barley hold onto the rod and I doubt its anywhere near 30kgs of drag.

-

Just received my new Stella in the post today and thought I'd share some pics and a little bit of a run down

The colour appears to be slightly darker than the press photos, overall better looking than I expected.

The bail arm has a slightly different design than the older model inside and out I think because it clicks over more easily than the 07' and feels more positive.

The Handle has a different knob made of a slightly harder material than the previous model. The handle can now be swapped side to side without changing the threaded insert, which on the 07 was a pain in the arse if you wanted to change hands on the go.

The line roller coating has been changed from titanium nitride to what appears to be Shimanos ARB coating. (as to whether it makes any difference...)

There is a different hole pattern in the spool which I quite like.

The drag knob has been changed from plastic to aluminum and it has a slightly finer adjustment and a much more positive feel.

In comparison to the 07 model it feels like less effort is required to turn the handle with a slight reduction in smoothness (this may improve with use as my previous Stella did) After a little bit of fiddling and adding some more oil, Ive got to say the smoothness is on par with the 07.

Overall everything feels a little tighter and more positive and a bit more well built.

Final thoughts; Little improvements overall make this reel a better package than the previous model certainly, but is this worth the extra $250-300?

As far as I'm concerned considering how good the 07 model is, the short answer is no.

2011 Update:

I've now had this reel nearly a year and I can say without a doubt its the best reel I've ever owned bar none.

-

I own the new FE Stella in the 2000 Size and I have used the 1000 FE as well.

FD is the previous model (2007) FE is the latest (2010)

I did a comparison of them on another forum (I'll do a copy and paste job and post it here)

-

Bugger the looks have you actually used one? I've got a new Stella and its the best reel I've ever owned.

I've had an Exist, A Steez, FD Stellas, New Certates etc the new Stella is better IMO.

-

The tides in the cooks on Saturday were very strange, changed direction at least 4 times in the few hours I was out.

I have never seen anything like it, the fish didn't seem to mind though!

-

As Leon pulled up on his bike I hooked up straight away just like the time before

Cheers Stewy

And the time before that!

-

Seems that every time I'm not fishing you brain it Stewy!

Last time I went down all I could manage was to lose $40 worth of lures (in two casts

) and get sunburnt.

) and get sunburnt. -

Bad luck on the jewie (I wanted a photo of it too)

I got well and truly dusted by something large a little further up a few weeks ago, I suspect it was a jew but didn't get a look at it.

Looks like a you had good session anyway.

I have to get motivated to start getting up early and go fishing before work again.

-

I saw you guys on the way to work, its good to see some fish being caught the Cooks was very slow for a while.

-

haha Slinky - I usually spot Forster posts!

Top info there, Dan!! Also, squidgie fish 'silver fox' work well with flatties too - specially if you can get between the racks!

Those atomics are working really well at the moment on bream - don't be afraid to move them slow, with plenty of pauses .... then throw in a fast bit, just for a change!~

Lots of australian salmon schooling off the beaches too - I watched 2 schools move along the Main Beach, well within casting distance. Small shiney metal slugs would go well for them!

They are catching quality bream from the breakwall, too, down towards the ocean end.

I've had jewie hits on the wall using live worms (put a whole one on with lots of dangling bits) they are like jellybeans to jews!

Also tailor fillets or even blackfish fillets. A few weeks ago, they were 'on' on the Tuncurry side - folk catching them all day!

Also tailor fillets or even blackfish fillets. A few weeks ago, they were 'on' on the Tuncurry side - folk catching them all day!I hope to be out in the yak at some stage - so if you see a grey Hobie Sport & a person with a 'holey hat' it could be me!!

Cheers

Roberta

Thanks for the help. I've got some atomics and squidgy fish, sounds like I'm set.

I'm actually a bit disappointed, now I don't have an excuse to go and buy more lures

Ahhh who am I kidding, off to the tackle shop....

Cheers,

Meh

-

G'Day mate , I grew up in Forster and my dad had a tackle store there, so I have fished it a lot. Fishing with Shallow diving atomics over the weedbeds and along the shorelines can produce some great flatties and bream , as for plastics, the gulp grubs and shrimp have worked well for me in the natural colours they are great to cast around the washboards on the oyster leases and off the shoreline . If your targeting bream I would cast along those washboards and over the patchy weed areas in the paddock, use light jigheads 1\16th or less . flattys will be found in the paddock as well but I would be using a heavy 1\8th or so jighead to maxamise your casting distance and contact with the bottom . Blades work well around the bridge and the sandbanks around that area , but fishing the bridge can be hard on a big tide due to the strong current . The whiting might be a bit tougher in the winter , but your still a chance . Usually I fish for them solely with surface lures but I only do this in the warmer months , it's just to cold for consistant fishing on the surface IMO. Consistant fish can be found around the oyster leases that you can see as you drive over the bridge , you are a good chance if you cover those areas with your plastics . The Breakwall at Forster is a great spot for jew , but you will need some really heavy jigheads or internally waited plastics , heavy leader as well . The current going out the breakwall is really strong so if you fish with something like a slick rigg it will often just get washed out as fast as you can wind in the slack , fish the wall around the turn a hour or so each side. Metals can work off there but im not sure whats around at the moment , anyway I would be casting for a jew , it's hard work but if you get one it will be 10kg plus , you don't see many small ones getting caught .

Good luck and tight lines

Cheers Dan,

Looks like I've got bases covered in terms of lures.

A nice jewie would be a welcome addition, Ill be sure to give it a try!

The Grass was definately GREENER

in Fishing Reports

Posted

I know that area pretty well, good to see fisheries down there wrong time though.

They should get down there on a Friday or Saturday night they would have a field day.